Phoenix locos are UK based international distributors of high quality, affordable battery electric model locos,

rolling stock and loco bogies in 5 inch and 7.25 inch gauge that are ideal as club locos or in garden railways.

40HP Simplex Protected Loco Freqently Asked Questions

Will you do a 5” gauge version?

We offer the loco gauged to 7¼” as standard. We can also re-gauge it to 5” gauge. We are not currently planning a dedicated 5” gauge version but, if we get enough requests for one, we will produce it.

What do you get with a Tin Turtle kit?

There are over 900 individual components including fasteners and brackets. Main components are chassis; chassis cover plates, cab doors and bonnet panels, buffer beams, brackets, suspension units with self aligning bearings, wheels, axles, taper lock sprockets, chain, and motor-mounting bracket. DC motor, motor-drive sprocket, motor speed controller, handset, fuse holder and fuse, all wiring, handles, detailing brackets, door and hinge strips. Illustrated instructions, all fasteners and decal set.

Do you need special paint?

You will need to purchase a small amount of paint. Most car spray suppliers will supply the correct colour to match the loco. We supply the correct colour codes with the loco. We have all the structural parts powder-coated. This is an industrial process whereby the bare metal part is electro-statically charged and the coloured powder is blown on to it. The part is then baked in an oven to provide a durable industrial finish. This process is commonly used on domestic appliances such as washing machines and cookers and by the bicycle and car industries.

All the main structural panels are supplied flat and powder coated in Drab Olive Green as standard. You will need to paint the brackets and small detailing parts such as the handles and couplings.

We can also arrange special colour schemes at additional cost.

What happens if I scratch the powder coat finish?

Unfortunately scratches and marks are a consequence of a hard working loco. The powder coat finishes we use are all taken from a standard colour range called the RAL colours, we supply the code for your loco colour and you can purchase touch up paint to match your loco and treat it the same way you would with any scratched, finished part. We particularly recommend enamel paints as they are thicker and closely replicate powder coat finishes in thickness and texture.

Do you need engineering skills to build the kit?

Absolutely not, the kit is designed to be built with hand tools only. We do all the machining and supply all fasteners. We would recommend that you have somebody to assist in the build up as it can get quite heavy to move around and a second pair of hands make curving and fixing the front and rear bonnets very much easier. The comprehensive illustrated building guide takes you through the whole process of building your loco.

What is involved in the building process?

The following list demonstrates the principal stages in construction.

You can also download sample pages from the build manual.

- Make up the wheel-sets onto the axles

- Make up the buffer beams and add detailing

- Bolt the buffer beams in place

- Make up the side skirts and front and rear body panels

- Bolt the skirt brackets in place and bolt skirt to chassis

- Make up the lay-shaft and bolt into place

- Bolt the wheel sets in position and add drive chains

- Turn chassis upright and add front and rear bonnets

- Fit the DC motor and chain drive

- Bolt the doors in place

- Add the body side and door detailing

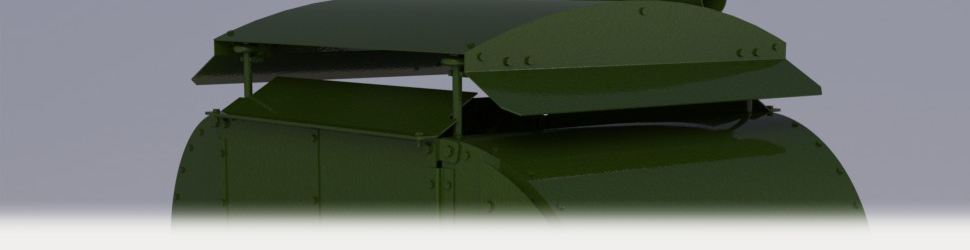

- Fit the roof panel to side roof panels

- Add the protection armour to the cab/roof sides

- Install the pre-wired control loom and battery leads

- Install batteries

- Fit roof

- Go for a test run.

The kit comes with comprehensive illustrated instructions and we are always happy to demonstrate any stage of the build and we are also happy to discuss any aspect of Tin Turtle ownership at any stage.

How long will it take to build a Tin turtle?

The kit has a lot of components but there are a lot of small sub assemblies that are repetitive and can be done off the loco.

One of the main jobs is to fit the front and rear bonnets which are supplied as flat panels and are curved as they are fitted to the loco. We achieve this by using a double bracket and offset holes in the side and front panels. There are 36 double brackets which need to be made up by bolting two brackets together. This can be done at the bench and then installed in the loco.

Overall build time will be around 30 to 40 hours.

Is there a choice of graphics?

Tin Turtles had very little graphics, basically a WD Loco number and a Motor Rail Company works plate. We supply decals for both.

Custom graphics can also be supplied.

Will it fit in my car?

We have scaled the loco at close to 1/3rd full size, which makes the model a very practical 812mm mm (32ins) long.

Do you offer a warranty?

Yes, we do, subject to certain conditions we guarantee your locomotive for 12 months from day of purchase. The motor speed controller is warranted for an additional 12 months. We will repair or replace any item, which fails. We do however exclude items that have been mis-used.

What kind of delivery time can I expect?

We have these locos in continuous production and can usually supply one within 6-8 weeks. The choice of colour is usually the governing factor with delivery. Although the powder coating process is fairly quick, it is governed by the availability of the colour and the fact that the process can only do one colour at a time. However, the finish is very robust and saves an enormous amount of painting!

What else will I need for my Loco?

You will need two 12v batteries. We can advise on type and size and we can supply if required.

You will also need a battery charger.

You will also need a small amount of paint to finish some of the smaller detailing parts.

How do I place an order?

You can order by telephone, mail or email.

Payment can be made by credit or debit card, cash, bank transfer (BACS) or cheque.

You pay a deposit with order and the balance on collection or prior to shipping.

Do you deliver?

We can arrange delivery by carrier at extra cost or you can collect your Simplex Loco from us.

We can arrange delivery worldwide with a few exceptions. Please contact us for further details regarding export sales.

Meta Information

For all current pricing, please contact Miniture Railway Workshop