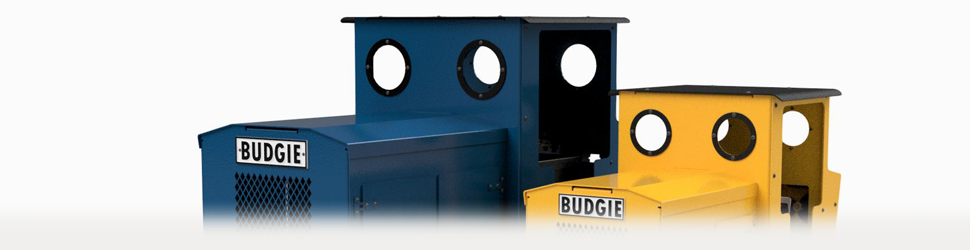

Phoenix locos are UK based international distributors of high quality, affordable battery electric model locos,

rolling stock and loco bogies in 5 inch and 7.25 inch gauge that are ideal as club locos or in garden railways.

Lifting The Lid

Battery-electric locomotives are like human beings. The heart of any battery-electric locomotive is the battery. The motors provide the muscle and the motor speed controller is the brain.

You can’t tell whether a person is a rocket scientist or a railwayman just by looking at them and it is the same with motor speed controllers. They all function, but some function better than others.

We were looking to have a controller system made specifically for locomotives that would have the following features.

- Reliability

- Digital, high frequency operation

- Regenerative braking

- Easy to install and use

- Deadmans facility

- Good design

- Over temperature protection

- Integrated heat-sink

- Easy to mount

- Reasonable cost

- Water protection

- Safe to operate

- Options for accessories

- Handset included

- Failsafe mode

- Good technical back up

- Upgradeable firmware and software.

- Double heading facility

- Intelligent control

- Soft start/stop

- Smooth power control.

- Good warranty.

- Local manufacture and supply

DC motor speed controllers are made all over the world. The companies that make them are often part of a bigger industrial combine. They make great products, however, they do not make them specifically for the locomotive market, as that market is too small. There is always a compromise and you have to use the product that is the closest to your wish list, usually a golf buggy controller.

We have been working closely with Mtroniks in Yorkshire to develop a new controller that meets the demands of the modern market and can be retro fitted to improve the performance of older locos.

Mtroniks have been designing and manufacturing motor speed controllers for more than 20 years and have produced more than a million controllers in that time. The controllers are designed and manufactured in house and were developed around a large powerful computer core to add extra features and exceptional control function.

What's in the box?

The DCi120 controller contains a powerful computer chip which converts the input signals from the driver via the handset to commands for motor speed and direction. The components are sealed to provide water protection and to stop dust and dirt getting into the system. The whole controller is mounted onto a extruded aluminium base-plate to allow for easy mounting in any position.

The top of the controller has four stud connectors with M6 nuts for easy connection to the batteries and motors, mutiple motors can be connected directly or via a terminal block.

There is also an input socket for the handset and a12 volt output for accessories. Look out for a multiple accessory relay board in the near future.

The other little socket is a factory programming port which allows us to update software and programme the controller. it also allows us to interrogate the computer chip for fault finding along with running and usage history.

The bit you hold in your hand

The handset has a rotary power controller in the centre. This has a centre neutral position, turn to the right to increse power and speed, turn it to the left of centre and you will decrease the power and bring in the regenerative braking. This means you can coast into the station, adding a little braking to bring your train to a gentle halt at exactly the right spot every time.

We have programmed in soft start and stop, so there will be no jerky starts or surprise sudden stops.

Direction of travel is decided with a toggle switch and the whole system can be turned on and off at the handst by using the master switch at top left of the handset. The horn button is top right and triggers the 12v output on the main controller board.

We have also fitted a deadmans facility with a jack socket on the trailing edge of the handset. the jackplug has a lanyard for your wrist and in the event of a runaway the jackplug will be pulled out and the controller will take off the power and stop. The jack socket will also accomodate a foot switch or other types of switching to suit your loco and circumstances.

The connection between the controller and the handset uses a protocol called I2C which is a computer program designed to allow machine tools to communicate with each other. By Using an industrial standard protocol we have reduced the number of wires connecting the handset which increases reliability and adds the options to add accessories in the future.

Safety

Before releasing the production versions, we have been field testing the prototypes for some months, for field testing you could also read "trying to break them". The paramount aspect of testing is safety. The system is designed to go to zero should there be a break in connection. This means that should the connecting lead be severed or inadvertently disconnected the computer will shut down the system and the loco will stop. The deadmans facility will also bring the loco to a stop and take off the power. Both events will require the driver to re-set the system by turning of and resetting the power.

As well as inadvertant disconnection we also need to guard against false starts and sudden acceleration. The handset has a seperate on/off switch to allow the user to make all connections before powering up. The rotary control must be in the neutral postion when the system is switched on, if it is not in neutral then the system will not operate and will need to be reset by turining the rotary control to the neutral position and turning the pwer of for a few seconds and then back on. This function stops any possibility of the throttle being open when power is applied and the locomotive accelarating away.

Further to this we have also programmed the system to have soft start/stop, This feature is particularly useful with novice or younger drivers as it softens the throttle inputs to stop massive initial acceleration and unsettling the passengers.

What you get with the system:

- The controller

- The handset

- Crimp terminals for batteries and motor

- 60 Amp midi fuse

- Related wiring

- Illustrated instructions

The price is £225 inc Vat

The system is a new departure in the battery/electric locomotive control market and incorporates many new features and the latest technology, we will be fitting this system to all Phoenix DC motor locomotives in the future and we are offering the sytem as a replacement for older systems or for new build locos. To ensure complete customer satisfaction we will be releasing the DCi 120 with an industry leading 24 months warranty.

Meta Information

Showing posts from July 2010. There is 1 post that matches your critera.